How to check a faulty starter motor

0 Comments

Add Comment

Welcome to the HDM’s Auto Electrical Technology Blog. Our blog is dedicated to providing expert information on auto electrical parts and solutions. Here you will find informative articles on everything from part selection to troubleshooting auto electrical problems and maintenance tips. At HDM Auto Electrical Parts, we are dedicated to helping Auto Electricians and Vehicle Owners get their vehicles on the road fast. Subscribe to stay up to date with the latest parts specials, product reviews, and how-to guides for Auto Electricians.

07/09/2023 13:52

Internal combustion engines cannot start themselves; they require input from an external source of energy in order to get going. This starting process may be electrical, hydraulic, or pneumatic, depending on your preference.

In most vehicles, this function is carried out by electric motors, which are more commonly referred to as starters or starter motors. Because of its strong starting torque, the DC series motor is an excellent choice for use as a starter motor. This is because it is necessary to overcome significant levels of friction and compression resistance during the starting process.

Your electric starter motor engages when you turn the ignition to “run.” The starter turns the engine over allowing it to suck in air.

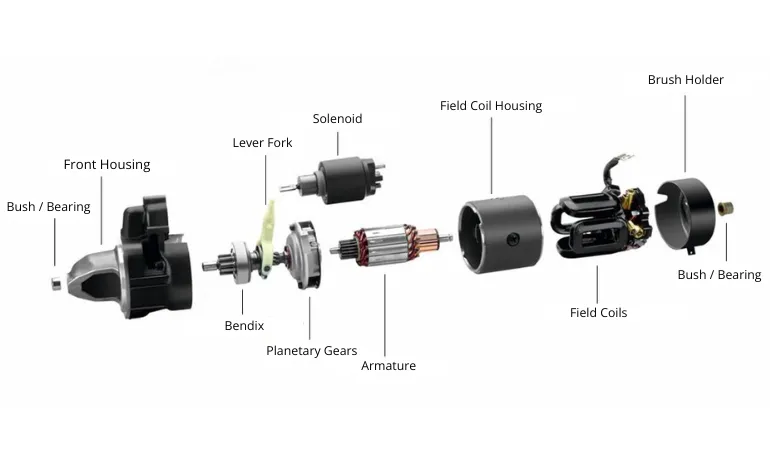

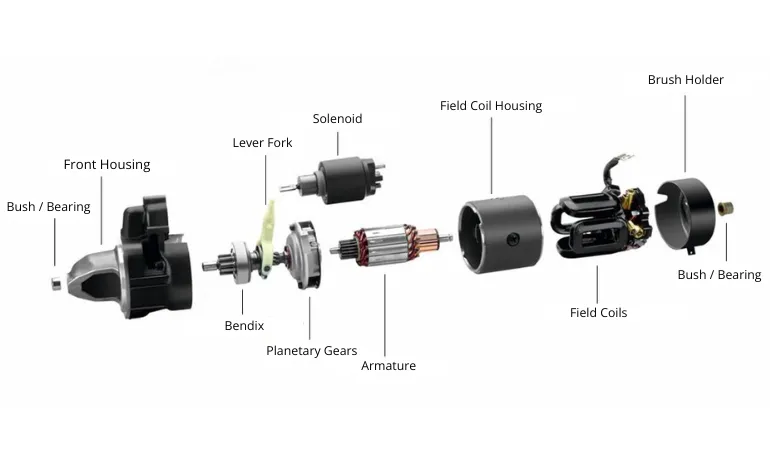

On the engine, there is a flex plate or flywheel, with a ring gear around the edge, that is attached to the end of the crankshaft. On the starter, there’s a gear designed to fit into the grooves of the ring gear (the starter gear is called a pinion gear or Bendix drive).

When you turn the ignition switch, the starter motor is energized, and the electromagnet inside the starter motor body engages. This pushes out a rod to which the pinion gear is attached. The gear meets the flywheel, and the starter turns. This in turn spins the engine over, sucking in air (as well as fuel). At the same time, electricity is sent through the spark plug wires to the plugs, igniting the fuel in the combustion chamber.

As the engine turns over, the starter disengages, and the electromagnet stops. The rod retracts into the starter once more, taking the pinion gear out of contact with the flywheel and preventing damage. If the pinion gear remained in contact with the flywheel, it’s possible that the engine would spin the starter too fast, causing damage!

A faulty starter motor can exhibit several symptoms, but the four main ones to look out for are:

The main causes of the symptoms associated with a faulty starter motor include:

For the starter to work properly, the power source must be fault-free. The diagnostics for the fault should take into account the starter's positive and ground connections as well as the vehicle's battery.

Overloads are the main reason for electrical problems with the starter. This may show up as ground and winding short circuits in the field and armature winding, but it may also appear in the control element coils (solenoid switch) on occasion.

High loads are placed on carbon brushes and collectors, which makes them more prone to problems than the alternator. Clamping carbon brushes in the starter, for instance, results in the production of considerable arcs because of the high currents, whereas clamping carbon brushes in the alternator does not cause voltage to arise and thereby relieve the alternator. Frequently, these arcs damage or destroy the collector. For troubleshooting, a multimeter and a clip-on ammeter are necessary. However, acoustic perception can also be used to find fault sites (like the pinion).

CAUSE

When low beam lighting is switched on it is weak or not working:

SOLUTION

CAUSE

Solenoid switch does not energize, Bridge terminals on the starter.

Starter runs / engages =

SOLUTION

CAUSE

Solenoid switch energizes:

SOLUTION

CAUSE

SOLUTION

CAUSE

SOLUTION

CAUSE

SOLUTION

CAUSE

SOLUTION

CAUSE

SOLUTION

Looking for a starter motor part and you want to know the price and availability from HDM? Tell us what you are looking for and one of our Starter Specialists will phone you back within 20 minutes with the price and information you need. (Please Note: This applies to office hours. If you contact us after hours, we will call you the next business day)